Engineering

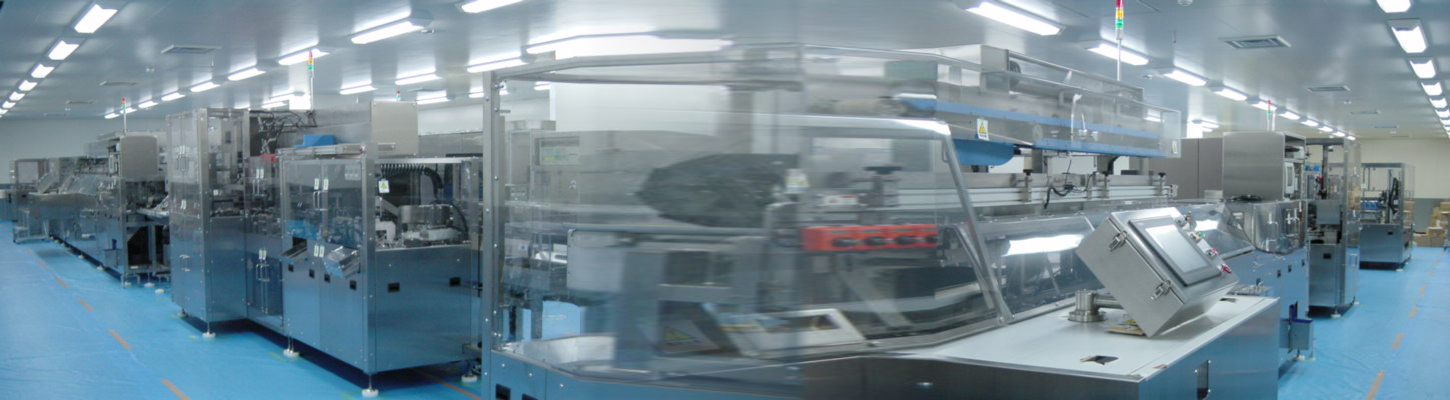

Pharmaceutical production line involves a variety of processes from medicine manufacturing to packaging. Ease Limited does not only provide customers what they need but also with some added values — higher operability and easier maintenance. In addition, our validation service (verification and documentation) which strictly observes current regulation ensures that the design, installation, operation and function of the delivered unit or system fulfill the required specification and intended purpose of use.

Licenses

- Construction Business License 「Tokyo Metropolitan Governor (HAN-6) No. 159518」

Ease Limited is licensed to conduct installation of manufacturing systems, machines and equipment etc. - General Worker Dispatching Undertakings License No. HA13-304694

Ease Limited has a long experience of dispatching professional staffs to construction sites or engineering companies for various pharmaceutical projects (design, validation and management, etc.)

Services

- Installation of new production/packaging equipment (from basic engineering to validation)

- Relocation of existing production/packaging equipment (from pre-relocation operation check to validation after relocation)

- Various modification works (from modification design to validation)

- Execution of validation, and documentation support (creation of high-level documents such as VMP)

- Execution of GMP qualification activity on hardware

(Execution and document creation or support of DQ, IQ,OQ, CSV (system assessment) for various equipment) - Support in documentation, equipment design and execution of qualification, which comply with various regulations or guidelines such as PIC/S-GMP, WHO-GMP, cGMP, EU-GMP, ICHQ9「QRM」, ISPE Vol5「C&Q」, etc.

- Compliance to ER/ES, GAMP5 and MHLW’s Guideline on Management of Computerized Systems

- Translations of documents (Japanese/English)

Product brochure, specification, operation manual, validation documents、law/regulation, guideline, etc.

Consulting

Medicinal product affects human life. Therefore, its quality must uniformly fulfill the required criteria.

Ease Limited’s experienced consultants with expertise in pharmaceutical GMP (Good Manufacturing Practice) and give you the answer how your manufacturing site and operation procedures should be, through simulated GMP inspections, diagnosis, trainings and seminars which will help to remove your anxiety. For promotion of GMP knowledge, we regularly hold open seminars and actively submit articles to specialty magazines, journals and papers.

Area of Consulting

- GMP inspection by PMDA (Japan)

(API/Sterile/Non-sterile/Biological/Regenerative/Clinical/Package・Label) - GMP inspection by FDA (US) / EMA (EU)

- PIC/S GMP Guideline(GMP/Validation)

- CSV (Computerized System Validation)

- ICHQ9 (Quality Risk Management) / ICHQ10 (Pharmaceutical Quality System), and others.

Consultants Profile

Contracted Ex-PMDA GMP inspection experts (Pharmaceutical and Medical Devices Agency)

-

Hirotaro Yorozu

Ex-PMDA GMP inspection expert

Ex-PMDA GMP inspection expert

Built his career at Roche Japan, PMDA and Teva Pharmaceuticals. Presently belongs to NPO-QA Center as a consultant/advisor for general contractor and pharmaceutical companies, and gives GMP lectures and presentations as well. Experienced a number of pharmaceutical GMP inspections of domestic and overseas sites in both ways as being inspected and as an inspector.

Services

Simulated GMP Inspection

Simulated GMP inspection by Ex-PMDA GMP experts provides the best opportunity to know what the real GMP inspection would be. Also it is a good practice of Q&A communication with inspectors. Be familiar in advance with points to consider in communication with inspector and points which are likely to be checked.

GMP Consulting

Various GMP trainings based on Japanese, US, EU guidelines are available.

- Create PIC/S-compliant Validation Master Plan/Validation Summary Report

- Create PIC/S-compliant Site Master File

- Create ICHQ9 (Quality Risk Management) / ICHQ10 (Pharmaceutical Quality System) - compliant SOP

- Observe CSV (Computerized System Validation) guidelines

- Compliance with GMP inspection by foreign GMP authorities : FDA(US) /EMA (EU)

- Compliance with GMP inspection on clinical drugs, etc.

GMP Seminar

- Exclusive seminars and on-site seminars by Ex-PMDA GMP experts

- GMP/GDP Seminars focused on pharmaceutical packaging are also available, such as:

Exclusive Seminar(About 2 to 6 persons)

Practical and well-focused seminars which consist of GMP inspection outlines, product-specific points to be checked for API/Biological/Sterile/Non-sterile drugs, CSV and PIC/S compliance, etc.

It takes place in a small group in order to focus on specific needs and questions of participants and encourage active Q&As.

On-site Seminar(Any number of participants)

Practical seminars focused on the phases from preparation for PMDA GMP inspection to the correction of findings as the result of inspection. Good opportunity to study risk assessment for manufacturing site, product and method, as well as risk-based approaches throughout the process from staring material acceptance to final product shipment. Learn in advance the points to be checked by GMP inspection and practice a manner of communication with inspectors.

– Packaging line engineering

– Selection of items to be qualified in the view of Risk Management – PTP machine –

– Risk control and validation – for pharmaceutical packaging process

– Unique Device Identifier and FDA regulation (USA)

– Country-specific regulations on GS1 codes used for pharmaceutical packaging

Instruments

Drug products must meet requirements of a country where it is marketed. Talking about packaging and labelling, today’s regulations delicately vary from country to country. Ease Limited, in collaboration with partner companies, has developed systems for packaging/labelling process which comply with various country-specific requirements. We also develop a wide range of inspection systems for pharmaceutical and food/beverage manufacturing lines.

- Track & Trace

Serialization System (HIES-5000SZ)

Aggregation System (HIES-7000AG) - Inspection System

Pulsed X-ray inspection system for missing content, breakage or crack on packaged content, foreign particles inside, etc. - Picture Recording System

“Mie-reco”, monitor recorder for production lines